40 aluminum silicon phase diagram

The Al-Si Phase Diagram The binary Al-Si phase diagram was initially studied by Fraenkel of Germany in 1908. It is a relatively simple binary diagram where there is very little solubility at room temperature for Si in Al and for Al in Si. Thus, the terminal solid solutions are nearly pure Al and Si under equilibrium conditions. 50 Multicomponent Phase Diagrams: Applications for Commercial Aluminum Alloys (C) 3.5" (AI)+Mg2Si+(Si) [555 X] Si, % Figure 2.1 {continued) aluminum in addition to Mg and Si, and coherent ^" phase contains an excess of silicon with one of the possible formulae Mg5Si6 (Marioara et al., 2001). The pre

The characteristics of a number of phase equilibrium diagrams of systems containing aluminum and scandium (Al−Sc, Al−(Li, Mg, Zr, Mn, Cu, Zn, Si)−Sc, Al−Mg−(Li, Zr)−Sc) were investigated in the high-aluminum range. A small, but significant, solubility of scandium in solid aluminum was observed, which was little affected by the presence of a third component. Ternary compounds in ...

Aluminum silicon phase diagram

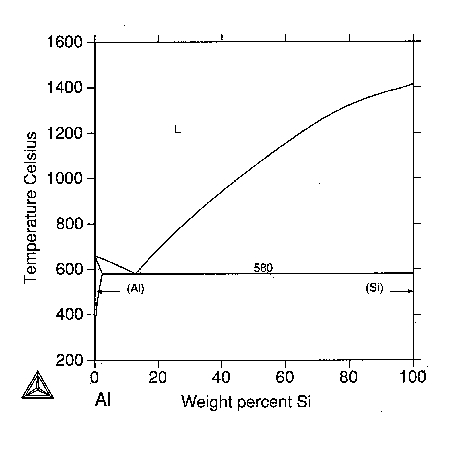

This phase diagram is for high-purity Al–Si alloys. The two solid phases are labeled (Al) and (Si). You must be aware that Al stands for aluminum as a component (and as an element), whereas (Al) stands for the phase which may be a solid solution. The relationship between composition and the hot cracking of restrained castings in binary aluminium – silicon alloys is shown in Fig. 10.4 and the corresponding section of the aluminium–silicon phase diagram in Fig. 10.5. The degree of cracking rises to a maximum at about 0.5 % silicon and then decreases rapidly as the alloy content is increased. Search Search en Change Language Upload Read free for 30 days User Settings Skip carousel What is Scribd? Books Audiobooks Magazines Podcasts Sheet Music Documents (selected) Snapshots 0 ratings0% found this document useful (0 votes) 208 views 1,032 pages TM 1 1500 323 24 1 Original Title:TM-1-1500-323-24-1 Uploaded bybetodaap...

Aluminum silicon phase diagram. Aluminum •"Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. This Tech-Note is devoted to a study of the aluminum-silicon phase diagram, a diagram of considerable commercial significance. The binary diagram is the starting point for developing more complex alloys and for understanding their behavior. Elements such as Si and Fe are common impurities found in aluminum alloys, but silicon The silicon content in standardized commercial cast aluminum-silicon alloys is in the range of 5 to 23 wt%. The structure of the alloys can be hypoeutectic, hypereutectic, or eutectic, as can be seen on the equilibrium phase diagram (Fig. 1.1a). The properties of a specific alloy can be attributed to the individual physical Download scientific diagram | a) aluminum-silicon phase diagram, b) schematic of a phase diagram for faceted/non-faceted eutectic phase diagram. from publication: M. Shamsuzzoha and Frank R ...

Phase diagram. Aluminum End of Al-Si Phase Diagram. The melting characteristics of the cladding alloys are governed by the Al-Si phase diagram. The eutectic composition, i.e. the amount of Si required to produce the lowest melting point is 12.6%. The melting point at this composition is 577°C. At lower Si levels the solidus or the point at ... UC3M Equilibrium diagram : Map of the phases in thermodynamic equilibrium that are present in a system of... globules of tin-rich intermetallic phase (light) in a matrix of dark indium-rich intermetallic phase. b)! Al-13%Si. Acicular structure consisting of short, angular particles of silicon (dark) in a matrix of aluminum.... Locate the eutectic composition in the aluminum-silicon phase diagram Calculate the amount of each phase in the eutectic micro constituent. Based on the amount of each phase, which should be continuous? Would you expect the eutectic micro constituent to be ductile or brittle? 100 10 20 30 Atom perico 40 50 60 Temperature, "c 200060 OX 60 s 125 1000 Open Access Published: 13 July 2016 Subtractive Color Filters Based on a Silicon-Aluminum Hybrid-Nanodisk Metasurface Enabling Enhanced Color Purity Wenjing Yue , Song Gao , Sang-Shin Lee , Eun-Soo Kim & Duk-Yong Choi Scientific Reports 6, Article number: 29756 (2016) Cite this article 1115 Accesses 36 Citations 0 Altmetric... Advertisement View all Nature Research journals Search Login Explore content Journal information Publish with...

Jan 15, 2022 · This phase diagram shows that disordered fcc structure is stable and precipitation of L1 0 phase cannot occur in the present alloy at 500 °C. Furthermore, L1 0 ordered phase has no solubility of Fe during the calculation using the TCHEA1 database in contrast to the compositions of Fe in the NiMn-rich region in Fig. 6(e)–(h). The Al-Si phase diagram is the base component system for the Al-Si series of alloys. As Figure 1 shows, it is a binary eutectic type phase diagram with limited aluminum and silicon solubility. The melting temperature of pure aluminum is 660°C. The solubility of silicon in the aluminum melt reaches a maximum of 1.6 wt.% at the 577°C eutectic ... Silicon has a very low solubility in aluminium; it therefore precipitates as virtually pure silicon, which is hard and hence improves the abrasion resistance. Phase diagram reproduced with permission from Mikael Schalin, Royal Institute of Science and Technology, Stockholm. Fig 2 ture for (a) Mg2Si in aluminum with an Mg-Si ratio of 1.73-to-1 and (b) magnesium and silicon in solid aluminum when both Mg2Si and silicon are present sometimes be deduced by refined studies of diffuse x-ray scattering. Under favorable conditions, GP zones can be seen in trans- mission electron micrographs.

Al-Si diagram is a eutectic diagram where solid solubility at least of aluminium in silicon is negligible, and maximum solubility of silicon in aluminium (at eutectic temperature) is 1.65%. The eutectic composition is 12.7% silicon. Fig. 3.18 illustrates this diagram and photomicrographs of alloys at room temperature.

Download scientific diagram | 4 : Aluminum – silicon phase diagram and microstructures [2]. from publication: Lost foam casting of LM6-Al-Si cast alloy | In the present research, experimental ...

To apply the basic concepts of phase diagrams to binary aluminium alloys. To extend the discussion to an outline of ternary phase diagrams, and to show how a so-called pseudo-binary section can be applied with benefit to the Al-Mg-Si system for alloys balanced in Mg2Si. Date of Issue: 1999 EAA - European Aluminium Association

Phase diagram for light metals Aluminum-Lithium. There are five phases illustrated; however the BCC Lithium end-member phase shows such limited Aluminum solubility that it hardly appears on this plot. There are two eutectics and one peritectoid reactions. The LiAl( ) and Li 2

The extent of the solid solubility region can be plotted onto the phase diagram and labelled appropriately. A solid solution of (i.e. mostly A) is called and a... worthwhile to note that some elements that are alloyed have zero solid solubility; a good example is Al - Si alloys, where aluminium has zero solid solubility in silicon.

To evaluate the reliability of metal-carbon eutectic systems as fixed points for the next generation of high-temperature standards the effect of thermodynamic properties related to the shape of eutectic phase diagram on the freezing temperature is investigated within the context of the numerical multi-phase-field model. The...

mechanical properties : October 9-13, 1990, Beijing, China International Conference on Aluminum Alloys Aluminum alloys : structure and properties Aluminum-silicon casting alloys an atlas of microfractographs / [electronic resource] Phase diagrams of binary beryllium alloys Copper alloys : preparation, properties, and applications

Jan 06, 2022 · Quasi-phase-matching has long been a widely used approach in nonlinear photonics, enabling efficient parametric frequency conversions such as second-harmonic generation. However, in silicon ...

Among the different aluminium alloy systems, the most used is the Aluminium-Silicon (Al-Si) system with Si concentrations in the range of 5 to 23 wt.%. This alloy system has an eutectic point at 12.6 wt.% Si at 577 °C [2] as shown in the phase diagram in Figure 1. Si increases the fluidity of the molten metal, therefore improving the

Amorphous-Phase Silicon Thin-Films by Hot-Wire Chemical Vapor Deposition Seungil Park 1) ․ Hyung Yong Ji 1) ․ MyeongJun Kim... Schematic diagram on the formation of amorphous Si thin film. Table 1. The deposition parameters of amorphous Si thin film for... 트레이(aluminum tray) 에 올려놓고 HWCVD 프로세스 챔버에 투입시킨 후 350℃ 로 기판을 예열 하였다....

In this experiment, we confirmed that the hydrogen radical pretreatment is essential when the metal-catalyzed SiNWs are synthesized at lower temperatures than metal-Si eutectic temperature.#Aluminum catalyst #Silicon nanostructures #Phase diagram #Hydrogen radicals #Growth mechanism

Ageing Heat Treatment of Aluminum Alloys1 Content ... Si Phase Diagram. T C n e ing ing T Time eing t 500 520 540 560 580 600 620 640 660 680 700 0 5 10 15 20 25 ~ö Mg 2 Si) L L+Al Al Al+Mg 2 Si L+Mg 2 Si n. ... SEM images showing silicon particles exposed after a deep-etching procedure5. However, when hot worked, age hardenable aluminum alloy ...

Aluminum-Magnesium-Silicon Ternary Alloy Phase Diagram. Ternary isothermal diagram ( 427°C), crystal data, melting points. D.Ludecke, (1986) Phase Diagram and Thermochemistry of the Al-Mg-Si System, Z. Metallkde., 77 278-283.

Transcribed image text: 1 In the Aluminum-Silicon phase diagram the maximum solubility of Silicon in Aluminum is: Time left 1:25:35 of °C 1.500 Atomic percentage, silicon 30 40 50 60 10 20 70 80 90 stion 1,400 1,414° 1.300 L 1.200 1.100 1.000 900 LB 800 700 0 + L 660.452 600 577 1.6 12.6 B 500 900 L+B 800 700 Q+L 660.452 600 1.6 -577° 12.6 B- 500 400 300 AL 10 20 30 40 50. 60 70 80 90 Si ...

Publisher Summary. This chapter examines the phase composition of alloys that contain magnesium and silicon in the absence of copper. It mentions that the aluminum-magnesium-silicon (Al-Mg-Si) phase diagram can be used for the analysis of many wrought alloys of 6XXX-series and casting alloys of the 356.0 type, provided the concentration of iron impurity is low.

Aluminum-Magnesium-Silicon Ternary Alloy Phase Diagram of Phase Diagram Calculations on Teaching, Research and Industrial 12 instances of aluminum alloy phase diagram. If you have any questions or good suggestions on our products and site, or if you want to know more information about our products, please write them and send to us, we will ...

of silicon carbide (SiC) membranes while achieving good membrane performance is an important goal, but still a big challenge. To address this challenge, herein, a colloidal coating suspension of sub-micron SiC powders was prepared in aqueous media by employing aluminum nitrate nonahydrate as a sintering additive and was used...

The Al-Si phase diagram, a diagram of considerable commercial significance, is the starting point for developing more complex alloys and for understanding their behavior. Si is a common impurity in aluminum alloys, but it is also a deliberate alloying addition in both cast and wrought Al alloys.

Al-Si alloys differ from our "standard" phase diagram in that aluminium has zero solid solubility in silicon at any temperature. This means that there is no beta phase and so this phase is "replaced" by pure silicon (you can think of it as a beta phase which consists only of silicon).. So, for Al-Si alloys, the eutectic composition is a structure of alpha+Si rather than alpha+beta.

All Aluminum Conductor (AAC) AAC transmission cable, also known as aluminum stranded conductor is made from multiple strands of hard drawn 1350 aluminum alloy which is 99 % pure with a little bit of silicon, iron etc. it has very high conductivity and resistive to corrosion but very poor strength to weight ratio.

Indicates key paper 28Dix: E. H. Dix and A. C. Heath, "Equilibrium Relations in Aluminum-Silicon and Aluminum-Iron-Silicon Alloys of High Purity",Trans. AIME, 78, 164-194 (1928). (Equi Diagram; Experimental) Google Scholar

[Easterling, Kenneth E.; Porter, Phase Transformations in Metals and Alloys. Juan jimenez flores. Download Download PDF. Full PDF Package Download Full PDF Package. This Paper. A short summary of this paper. 37 Full PDFs related to this paper. Read Paper. Download Download PDF.

The Al-Si phase diagram is a straightforward, classic example of a eutectic system where each element has little, if any solubility in the other. Aluminum melts at 660.452 °C while silicon melts at 1414 °C. The diagram, from Murray and McAlister (Vol. 8, Metals Handbook, 8th ed., 1973, p. 263), shows the eutectic at 12.6 wt. % Si and 577 °C.

Aluminum-Magnesium-Silicon Ternary Alloy Phase Diagram. View/ Open. AlMgSi Phase Diagram from ASM Center (548.5Kb) Date 2013-12-03. Author. ASM International. Metadata Show full item record. Abstract. Ternary isothermal diagram ( 427°C), crystal data, melting points. This item URI

Characteristic of aluminum-silicon alloy paste which is applied on the rear side of PERC cell was investigated. The paste was made by aluminum-silicon alloy with eutectic composition to avoid the formation of void which is responsible for the degradation of the open-circuit voltage. Also, the glass frit component of the paste was...

The Aluminum-Silicon Phase Diagram and Eutectic Modifications. The articles and presentations that can be down-loaded from this web site are based upon work done by GFV while employed at Bethlehem Steel (1967-1983), Carpenter Technology (1983-1996), Buehler Ltd. (1996-2009) and Struers (2009-Present) and from the authors consulting work for ...

Aluminum - Tungsten Phase Diagram. Coefficients of Thermal Expansion and Resistivity Thermal mismatch between materials is a major source of concern in microelectronics.

Aluminium silicate (or aluminum silicate) is a name commonly applied to chemical compounds which are derived from aluminium oxide, Al 2 O 3 and silicon dioxide, SiO 2 which may be anhydrous or hydrated, naturally occurring as minerals or synthetic. Their chemical formulae are often expressed as xAl 2 O 3 ·ySiO 2 ·zH 2 O. It is known as E number E559

We present the phase diagram of Fe(CO) 5, consisting of three molecular polymorphs (phase I, II and III) and an extended polymeric phase that can be recovered at ambient condition. The phase diagram indicates a limited stability of Fe(CO) 5 within a pressure-temperature dome formed below the liquid- phase II- polymer triple...

The expansion of renewable energy and the growing number of electric vehicles and mobile devices are demanding improved and low-cost electrochemical energy storage. In order to meet the future needs for energy storage, novel material systems with high energy densities, readily available raw materials, and safety are required. Currently, lithium and lead mainly dominate …

ABSTRACT Alloyed silicon-germanium (SiGe) nanostructures are the topic of renewed research due to applications in modern optoelectronics and high-temperature thermoelectric materials. However, common techniques for producing nanostructured SiGe focus on bulk processing; therefore little is known of the physical properties of...

1.1. Al-Fe-Si PHASE DIAGRAM The Al-Fe-Si system is the basic system for the structure analysis of commercial aluminum alloys of the 8111 type, and binary Al-Si alloys which, as a rule, contain an iron impurity (Table 1.1). The aluminum corner of the Al-Fe-Si phase diagram is considered in detail by

Passivation, in physical chemistry and engineering, refers to coating a material so it becomes "passive," that is, less readily affected or corroded by the environment. Passivation involves creation of an outer layer of shield material that is applied as a microcoating, created by chemical reaction with the base material, or allowed to build by spontaneous oxidation in the air.

The tin-silicon phase diagram is a eutectic and the lead-silicon phase diagram shows a monotectic transition and a small eutectic transition but no solid solubility. Group 15. Silicon nitride (Si 3 N 4) is a ceramic with many commercial high-temperature applications such as engine parts. It can be synthesized from the elements at ...

Up to 70 wt% of zinc can dissolve in aluminium, followed by magnesium (17.4 wt%), copper (5.7 wt%) and silicon (1.65 wt%). We shall see that the addition of these elements can radically alter the properties of pure aluminium. Typical Phase Diagrams Typical eutectic and a peritectic phase diagrams are illustrated in Fig. 2; these two forms

Phase One: Concept Design Phase Two: Prototype Design Phase Three: Prototype Buildindustries process awards about us contact *********@********.*** Chicago Naples Santa Barbara

Interface in carbon nanotubes (CNTs) reinforced aluminium-silicon composites are studied via thermodynamic and kinetic analysis. A pseudo-phase diagram has been generated based on the thermodynamic...

Search Search en Change Language Upload Read free for 30 days User Settings Skip carousel What is Scribd? Books Audiobooks Magazines Podcasts Sheet Music Documents (selected) Snapshots 0 ratings0% found this document useful (0 votes) 208 views 1,032 pages TM 1 1500 323 24 1 Original Title:TM-1-1500-323-24-1 Uploaded bybetodaap...

The relationship between composition and the hot cracking of restrained castings in binary aluminium – silicon alloys is shown in Fig. 10.4 and the corresponding section of the aluminium–silicon phase diagram in Fig. 10.5. The degree of cracking rises to a maximum at about 0.5 % silicon and then decreases rapidly as the alloy content is increased.

0 Response to "40 aluminum silicon phase diagram"

Post a Comment